Minéralisation du carbone

Isotopic evidence of passive mineral carbonation in mine wastes from the Dumont Nickel Project (Abitibi, Quebec)

Materials and Methods

Experimental cells

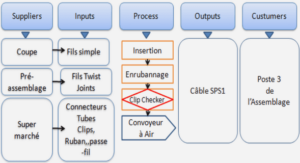

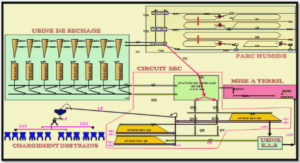

In July 2011, two instrumented experimental cells were built in the field to study the dynamic processes in waste rock piles and tailings storage facilities under ambient atmospheric conditions (Figure 2.1). Approximately 104 tonnes of heterogeneous mine waste rock ranging in size from blocks to silt was placed in the first cell (EC-1). The second cell (EC-2) contains 2.1 m3 of mine tailings produced from a pilot plant where the ore was processed in order to recover the nickel content. The run of mine ore was crushed and grinded in wet media with dispersant calgon (500g/t) and potassium amyl xanthate (PAX) (150g/t) to 80% minus 150μm. Then the pulp was deslimed in an hydrocyclone and separated using flotation. Finally, magnetic separation was conducted on rougher tails. The non-magnetic portion was brought back in a second stage of extraction in which the ore was crushed and grinded to 80% minus 74μm. The mine tailings emplaced in EC-2 were generated from both the slimes, fluff and rougher (non-magnetic) tails and are characterized by a D50 of 32.4 μm, a D10 of 2.2 μm and a uniformity coefficient (Cu=D10/D60) of 22.7 (Kandji, 2017). The mean porosity of the residues in EC-2 was estimated in the laboratory at 45%. The remaining hydrogeological parameters of EC-1 and EC-2 were estimated from the literature (Table 2.1) (Aubertin et al., 1996; Lechat et al., 2016; Molson et al., 2008, 2005, Peregoedova et al., 2014, 2012). A geomembrane (PVC Solmax 240) and a drain were placed at the bottom of each cell to collect the leachate for sampling. The main minerals in the waste are chrysotile, lizardite, brucite, chlorite and magnetite, whereas calcite and millerite were found in minor amounts (Pronost et al., 2012; 2010). Brucite is the key mineral for carbonation (Harrison et al., 2016, 2015, 2013; Kandji et al., 2015; Pronost et al., 2012), which in the DNP residues is found at up to 10.18 wt% (Assima et al., 2013a).

Table 2.1 Hydrogeological parameters of the experimental cells

In EC-1, interstitial gas sampling ports were made from 10 cm wide HDPE tubes perforated with 0.3 cm holes, located in the middle of the cell. In order to limit gas exchange with atmosphere, the tube contains successive 20 cm thick layers of silica sand overlaid by similar layers of bentonite. The sampling ports are placed in the sand layers for gas equilibration, and are connected to the surface with a Tygon tube. They are located at depths of 28 cm (Port 1), 70 cm (Port 2), 109 cm (Port 3), 150 cm (Port 4) and 190 cm (Port 5) below the surface of the cell (Figure 2.1-a).

In EC-2, the sample ports consist of a brass fitting (1.3 to 0.6 cm) covered with geotextile. The EC-2 sampling ports are also connected to the surface using a Tygon tube and are located at depths of 5 cm (Port 1) and 25 cm (Port 2) beneath the surface (Figure 2.1-b). Cell EC-2 also contains a Decagon 5TM probe to monitor changes in volumetric water content and temperature, and a Decagon MPS-1 probe to measure suction. Both of these probes are 4 cm below the surface. A weather station, located between the two cells, logs solar radiation, temperature, as well as wind speed and direction. Finally, a tipping bucket rain gauge measures rainfall.

Interstitial gases

Twice a month since July 2011, a peristaltic pump and a Vaisala Carbo cap probe (Model GMP343; ±5 ppmv) were used to sample and measure the CO2 concentrations within the interstitial air of the cells. A Wavelength-Scanned Cavity Ring Down Spectroscopy (WS-CRDS) instrument (Picarro G-1101-i) was used to measure the carbon isotope composition (δ13C) of interstitial CO2. Analyses were performed 5 times between August 2013 and November 2014, with results reported relative to Vienna Pee Dee Belemnite (VPDB) in per mil (‰). In EC-1, the WS-CRDS instrument was connected to the sampling port and the interstitial air was analysed for 20 min for CO2 concentrations and carbon isotope ratios. Repeated analyses of a standard gas ([CO2]= 420 ppmv +/- 8 ppmv; δ13C= -14.0 ‰ +/- 0,1 ‰) showed a measurement precision (1σ) of +/- 1.0 ppmv for CO2 and +/- 0.7 ‰ for δ13C. In the interstitial gases, the CO2 concentration may be lower than 400 ppmv therefore the precision of CO2 concentrations and δ13C is therefore given as the standard deviation measured using the WS-CRDS instrument (Figure 2.3, 2.4). After three analyses at different port locations, the reference gas was measured to correct for instrument drift. Since the internal pumping system of the WS-CRDS instrument did not allow sufficient gas flow for C isotope analysis in Cell EC-2, a peristaltic pump was used to pump the interstitial gases into 2 litre Tedlar bags over 3-minute periods. The bags were then connected to the WS-CRDS instrument and the gas was analysed following the same method as for Cell EC-1.

Core and surface crust samples

In waste rock Cell EC-1, white crusts, which had formed at the surface of most rock fragments, were also sampled using a Dremel drill. On the surface of Cell EC-2, scattered white crusts indurated the tailings at the edges of the cell. The white crusts were sampled from both cells 8 times between July 2012 and October 2015 (Tables 2.2 and 2.3). In addition, in the center of EC-2, tailings cores (14 cm to 32 cm length) were extracted using a steel tube. Cores were sampled in July and October 2012, and in July and November 2013, while between May 2014 and October 2015, cores were sampled 3 times a year in May, July, and October. All cores were split into 5 to 8 samples. To document processes and detect the carbonation front in more detail near-surface, the samples were thinner (1 cm) at the surface, increasing to 4 cm at the bottom, depending on the length of the core (see Supporting Information). The last core, sampled in October 2015, was 32 cm long. The first 15 cm of the core was divided into 1 cm length samples in order to describe more accurately the carbon content and isotope composition.

White crusts from EC-1 and EC-2 and core samples of EC-2 were crushed in an agate mortar for X-ray Diffraction (XRD), carbon content, and carbon and oxygen isotopic analysis. Selected samples of carbonate crusts and core were also impregnated with epoxy under vacuum to prepare polished thin sections.

X-ray diffraction

In order to identify the mineral phases, samples were analysed by XRD using a Siemens D5000 X-ray diffractometer (Cu-radiation). XRD patterns were collected with a scanning step of 1°/min (0.02° step size) over the 5-65° scattering angle range.

Scanning Electron Microscopy

A JEOL 840-A scanning electron microscope (SEM) equipped with an Avalon (PGT) energy dispersive X-ray spectrometer (EDS) was used to document mineral habits and textures and elementals compositions for mineral identification.

Total Carbon

The carbon content was measured with an Electra CS 800 carbon and sulphur analyser. Prior to analysis, the ceramic crucibles were placed in a furnace at 950°C to destroy residual carbon. The samples were then weighed and mixed with 0.18 cm3 of tungsten and 0.18 cm3 of iron. Two infrared detectors allowed identifying high and low-level carbon. High carbon content was calibrated using AR 4018 (1.30 +/- 0.05 wt% C), whereas UB-N serpentine ANRT (0.106 +/- 0.08 wt% C) was used for low carbon contents. Repeated analyses of standards AR 4018 and UB-N serpentine showed measurement precisions (1σ) of 0.2 wt% C and 0.03 wt% C for the high and low carbon contents, respectively. In order to test reproducibility of the measurements over time, the standards (Ar 4018 and UB-N serpentine) were analysed after three analyses.

Organic Carbon

The organic carbon content was measured using a modified Walkley-Black method (Walkley and Black, 1934). Approximately 2 g of sample were weighed and mixed with 10 ml of potassium dichromate (K2Cr2O7) (1 N) in an Erlenmeyer flask. Under a fume hood, 20 ml of sulphuric acid (H2SO4) was added. The preparation was stirred for 1 minute and left to rest for 30 minutes, after which 500 ml of distilled water is added to stop the reaction. Finally, 2 mL of barium sulfonate diphenylamine is added and the mixture is titrated using ferrous sulphate (Fe2SO4) (0.5 N). The carbon content is calculated using the following equation modified from De Vos et al (2007) where M is the molarity of the Fe2SO4 solution, V1 is the volume (mL) of Fe2SO4 needed in a blank titration, V2 is the volume (mL) of Fe2SO4 consumed in the sample titration, W is the weight (g) of the sample and CF is the correction factor. The need for a correction factor and its value are debated in the literature and depend on soil types and mineralogy. Here the results are reported using a correction factor of 1.32 (Chatterjee et al., 2009; Conyers et al., 2011; De Vos et al., 2007).

Carbon and oxygen isotope geochemistry

The carbon and oxygen isotope composition was determined at the Geotop Institute, Université du Québec à Montreal (UQAM), using a Micromass IsoPrime triple collector Isotope Ratio Mass Spectrometer (IRMS). The samples were weighed to obtain 100 g of carbonate, then placed into a borosilicate vial for a minimum of one hour at 90°C. Samples were dissolved using orthophosphoric acid and the CO2 produced was trapped for 15 minutes before measurement of isotope ratios by IRMS. The results are expressed in the notation in permil for 13CVPDB and 18OVSMOW.

The precision was ±0.05 ‰ for 13CVPDB and 18OVSMOW. Since the oxygen-isotope acid fractionation factors of hydrated Mg-carbonate minerals are not known, we followed previous studies (Bea et al., 2012; Oskierski et al., 2013b, 2013d, Wilson et al., 2014, 2009, 2006), and used the oxygen fractionation factor of magnesite (1.009228 at 90°C (Sharma et al., 2002) for all hydrated magnesium carbonates. An oxygen-isotope acid fractionation factor for calcite at 90°C of 1.00806 (Sharma et al., 2002) was used for the samples containing calcite.

Results

CO2 concentrations and isotope composition in interstitial gases

In the waste rock of Cell EC-1, the CO2 concentration of interstitial gases decreases from atmospheric concentrations (~390 ppmv) at the surface (Port 1) of the cell to ~50 ppmv at 190 cm (Port 4 ) from the surface (Figures 2.2 and 2.3). Air infiltration from the drain, which was used to sample leachate water, caused higher CO2 concentrations in Port 5, at the bottom of the cell (Figure 2.2-a). In the tailings Cell EC-2, despite the smaller thickness of the tailings materials (35 cm), the CO2 concentration still decreases from atmospheric values at port 1 (~390 ppmv) to an even lower concentration of ~25 ppmv at the bottom (Port 2) (Figure 2.2-b). Since 2012, within both cells, the CO2 concentrations at each position also tended to increase from year to year, except in Cell EC-2 for 2015 (Figure 2.2). During the winter, the interstitial gases were not sampled because of cold weather (Appendix1).

Figure 2.2 CO2 concentrations in EC-1 (a) and EC-2 (b) since July 2011

In Cell EC-1 using the WS-CRDS instrument, a decrease in CO2 concentration from ~390 ppmv at the surface to ~75 ppmv at port #4 (Figure 2.3-a) is associated with an increase of δ13C(air) , from circa -10 ‰ at the surface of the cell, to an average of ~ 1 ‰ near Port #4 (Figure 2.3-b). At the bottom of the cell, air infiltration through the leachate drain induces high CO2 concentration and low δ13C values (Figures 2.3-a and b). In EC-2, the decrease in CO2 concentrations from ~390 ppmv near the surface to ~75 ppmv (Figure 2.3-c) is also consistent with an increase in δ13C(air) from -10 ‰ to an average of ~3 ‰ (Figure 2.3-d). The CO2 concentrations measured using the WS-CRDS instrument in EC-1 and EC-2 are similar to values measured between May and November using the Vaisala Carbo Cap probe.

Newly formed carbonates and mineralogy

The newly formed minerals are difficult to identify because of the low modal abundance of carbonate minerals in the weathered mining residues and tailings. Nevertheless, crust and core samples analysed by XRD and SEM reveal nesquehonite, dypingite, hydromagnesite, aragonite [ CaCO3 ], and several minerals from the hydrotalcite supergroup minerals, including brugnatellite [Mg6Fe3+(CO3)(OH)13.4(H2O) ], pyroaurite 3R, and pyroaurite 2H [Mg6Fe23+(CO3)(OH)16.4(H2O)] (Tables 2.1 and 2.2). XRD data, however do not allow an accurate identification of the low-abundance hydrotalcite supergroup minerals. In EC-1, one sample (ECH 1 05-15) of a white crust contained artinite [ Mg2(CO3)(OH)2.3(H2O) ]. Well-crystalized primary calcite [CaCO3], was found in rock fragments from EC-1 (Appendix 3) .

The un-weathered mining waste that filled EC-1 contained 0.13 wt.% Ctot while the white crusts formed on waste rock fragments upon atmospheric weathering had a total carbon content between ~0.3 wt.% and ~6.2 wt.% Ctot (Table 2.2). Total carbon content of the samples containing primary calcite ranged from 0.5 wt.% to 10 wt.% Ctot. The non-weathered tailings residues in EC-2 are characterized by 0.08 wt.% Ctot whereas the crusts at the surface of the mine tailings (EC-2) had a total carbon content ranging from ~0.36 to ~5.3 wt.% Ctot (Table 2.3). Additionally, the total carbon content in tailings core samples ranged from ~1.33 wt.% at the surface to ~0.12 wt.% Ctot at the bottom of cell EC-2. More detailed information on the carbon content in core samples is provided in the supplementary information (Appendix 2).

Spruce needles and leaf fragments were found at the surface of EC-2. The organic carbon content was therefore measured in cores and in the surface crust samples in order to compute the inorganic carbon content from the total, referred to above. The crusts at the surface of EC-2 contained between 0.5 and 3.4 % Corg (Table 2.3) while in the core surface samples, the organic carbon content ranged from 0.4 to 1.1 %Corg. In some surface samples and below the first centimeter in the cores, the organic carbon content was below 0.4 %Corg, which is near the limit of detection of the Walkley-Black method (Tables 2.2 and 2.3). At these low levels, the organic carbon content might be overestimated (Conyers et al., 2011). Owing to the small quantity of material available, attempts to quantify the organic carbon content using larger samples (> 2 g) were not possible. Therefore, in samples for which the organic carbon content was below 0.4 %Corg , the total carbon content measured is considered to be inorganic carbon (see Table 2 and Supporting Information, Appendix 2).

|

Table des matières

CHAPITRE 1 Introduction, Problématique et Objectifs

1.1 Contexte Général

1.2 La minéralisation du carbone

1.2.1 Les réactifs

1.2.1.1 Minéraux naturels

1.2.1.2 Résidus industriels

1.2.1.3 Les résidus miniers

1.2.2 Les différentes voies de minéralisation du carbone

1.2.2.1 La minéralisation du carbone « in-situ »

1.2.2.2 La minéralisation du carbone « ex-situ »

1.2.2.3 Formes alternatives de minéralisation du carbone

1.3 La minéralisation passive du carbone

1.3.1 Dissolution du CO2 dans l’eau

1.3.2 Dissolution minérale

1.3.3 Précipitation des carbonates

1.4 Le Projet Dumont Nickel

1.4.1 Contexte géologique

1.4.2 La minéralisation

1.4.2 Plan d’exploitation des ressources

1.5 Problématique et objectifs

1.5.1 Projet RNC/UQAT/ULAVAL/CRSNG

1.5.2 Objectifs spécifiques et organisation de la thèse

CHAPITRE 2 Isotopic evidence of passive mineral carbonation in mine wastes from the Dumont Nickel Project (Abitibi, Quebec)

Résumé

Abstract

2.1 Introduction

2.2 Materials and Methods

2.2.1 Experimental cells

2.2.2 Interstitial gases

2.2.3 Core and surface crust samples.

2.2.4 X-ray diffraction

2.2.5 Scanning Electron Microscopy

2.2.6 Total Carbon

2.2.7 Organic Carbon

2.2.8 Carbon and oxygen isotope geochemistry

2.3 Results

2.3.1. CO2 concentrations and isotope composition in interstitial gases

2.3.2 Newly formed carbonates and mineralogy.

2.3.3 Carbon and oxygen isotope composition of newly formed carbonate

2.4 Discussion

2.4.1 Consumption of gaseous CO2 in interstitial gases

2.4.2 The carbonation process From gaseous CO2 to interstitial water

2.4.3 From interstitial water to solid carbonates

2.4.3.1 Theoretical isotopic compositions of interstitial waters and precipitated carbonate minerals

2.4.3.2 Precipitation of Carbonates

2.4.3.2.1 Waste Rock

2.4.3.2.2 Tailings

5. Conceptual model

CHAPITRE 3 Impacts of carbon mineralization on leachate water chemistry and quantification of atmospheric carbon sequestration in ultramafic mining residues from the Dumont Nickel Project.

Résumé

Abstract

3.1 Introduction

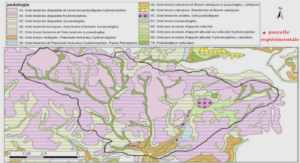

3.2 Geological setting

3.3 Materials and Methods

3.3.1 Experimental cells

3.3.2 Leachate water analyses

3.3.3 White crusts and core samples

3.3.4 Mineralogical analysis

3.3.5 Carbon content

3.4 Results

3.4.1 Field observations

3.4.2 Chemical evolution of the leachate water

3.4.3 Mineralogical analysis

3.4.4 Evolution of the carbon content

3.5. DISCUSSION

3.5.1 Impacts of atmospheric weathering on leachate geochemistry.

3.5.1.1 Transitional regime

3.5.1.2 Seasonal regime

3.5.2 Carbonate precipitation

3.5.3 Quantification of atmospheric CO2 sequestration

3.6 CONCLUSION

CHAPITRE 4 Modélisation numérique des processus de minéralisation du carbone à l’échelle d’une cellule expérimentale

4.1 Calibration

4.2 Discussion

CHAPITRE 5 CONCLUSION GÉNÉRALE

5.1 Principales contributions

5.2 Propositions de travaux futurs

References

ANNEXES

![]() Télécharger le rapport complet

Télécharger le rapport complet