Manufacturing rotorblades

LITERATURE REVIEW:

In this chapter a review of the relevant literature is presented, in order to better understand the principles of the project and explain the basic concepts pertinent to the work.

First, wood-plastic composites are introduced and the previous studies and different experimental approaches for material characterization are investigated. Furthermore, the fundamental knowledge of wind turbines, rotorblades, loading conditions, material requirements, and material selection for the rotorblades industry are presented.

Finally, the elastic and hyperelastic behaviour of materials is reviewed, followed by a brief description of the Artificial Neural Networks.

Wood-plastic composites:

In recent years, there has been an increasing interest in the development of woodplastic composites (WPC) for use as building materials, due to the abundance, low cost, and processability of wood as a filler. One reason that this fairly new material has outperformed competing plastic products in decking is that the addition of wood filler is an effective way to increase product stiffness, although strength usually suffers (Clemons, 2002). Using natural reinforcements such as wood in composite materials, instead of mineral reinforcements, has several advantages such as low density, low cost, and a less abrasive finish. The natural reinforcements are also non-toxic and recyclable .

The term wood-plastic composite refers to any composites that contain wood (of any form) and thermosets or thermoplastics. Thermosets are plastics that, once cured, cannot be melted by reheating. These include resins such as epoxies and phenolics. Thermoplastics are plastics that can be repeatedly melted, such as polyethylene and polyvinyl chloride (PVC) (Clemons, 2002). This study focuses on wood-thermoplastic composites, which are most often simply referred to as wood-plastic composites (WPCs) with the understanding that the plastic component is a thermoplastic.

Because of the limited thermal stability of wood, only thermoplastics that melt or can be processed at temperatures below 200°C are commonly used in WPCs. Currently, most WPCs are made with polyethylene, both recycled and virgin, for use in exterior building components. However, WPCs made with wood-polypropylene are typically used in automotive applications and consumer products, and these composites have recently been investigated for use in building profiles. Polystyrene and Acrylonitrile butadienestyrene (ABS) are also being used. The plastic is often selected based on: its inherent properties, availability, and cost; the product need; and the manufacturer’s familiarity with the material (Clemons, 2002).

The wood used in WPCs is most often in particulate form (e.g., wood flour) or very short fibres, rather than longer individual wood fibres. Products typically contain approximately 50 percent wood, although some composites contain very little wood and others as much as 70 percent.

Wood and plastics are not the only components in WPCs. These composites also contain materials that are added in small amounts to affect processing and performance. Although formulations are highly proprietary, additives such as coupling agents, light stabilizers, pigments, lubricants, fungicides, and foaming agents are all used to some extent (Clemons, 2002).

The principle of the identification program is based on the optimization of the estimated error between the values calculated theoretically and those obtained experimentally by means of the least squares method. In the area of structural behaviour, several studies are devoted to quasistatic problems (Verron, Pesseux, Derdouri, & Connolly, 1997) (Erchiqui, Derdouri, & Verron, 2001). For example, some studies focus on the case of blowing membranes, initially flat and circular (Verron, Pesseux, Derdouri, & Connolly, 1997). Others, such as the work of Rivlin (Rivlin & Saunders, 1951), Ogden (Ogden, 1972), and Erchiqui (Erchiqui, Derdouri, & Verron, 2001), are concerned with the case of hyperelastic materials. The remainder of the studies focus on viscoelastic materials, like those of Lodge (Lodge, 1964) and Christensen (Christensen, 1980). Identification of the mechanical parameters, according to these authors, is done in two stages. The first stage is to solve, in quasistatic regime, a system of nonlinear differential equations of the first order describing the equilibrium of the membrane. The results of this system provide the pressure values corresponding to deformation values. The second step is to optimize the error between the calculated and measured pressure values by use of the least squares method. Erchiqui has adapted this approach to determine the mechanical parameters of thermoplastics like ABS (Acrylonitrile Butadiene Styrene) and HIPS (High Impact Polystyrene) (Erchiqui & Derdouri, 2005). In addition to conventional techniques, in recent decades there has been a growing interest in the use of algorithms and stochastic techniques to solve problems of identification and physical simulations. One example of such a technique is the Artificial Neural Networks (Haykin, 1998) (MacKay, 1992). Erchiqui used this method for characterization of softened polymers (Erchiqui & Kandil, 2006). In this study, the Artificial Neural Networks approach is used in order to find the material constants.

Wind turbines:

Wind energy

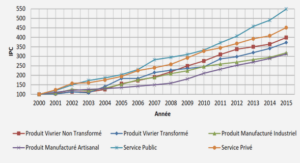

Renewable energy resources, of which wind energy is prominent, are part of the solution to the global energy problem. Over the past few decades, different types of materials such as wood, aluminium and composites have been used in manufacturing wind turbine blades. However, wood-plastic composites have not been developed to an industrial technical level for manufacturing wind turbine blades thus far. This PhD project focuses on the material characterization for wood-plastic composites and their potential application in the construction of rotorblades in cold climate regions, particularly in severe weather conditions characterized by temperatures below —50°C and wind speeds sometimes exceeding 25 m/s.

The rotor and rotorblades are exposed to external loads. These originate from the wind and from gravity. The operational parameters and conditions lead to the following requirements focused on stiffness, density, and long-time fatigue (Brandsted, Lilholt, & Lystruo, 2005):

• High material stiffness is needed to maintain optimal aerodynamic performance

• Low density is needed to reduce gravity forces

• Long-fatigue life is needed to reduce material degradation

Over time, different types of composite materials have been developed and used in manufacturing rotorblades. Carbon and glass fibre composites have been extensively used over the past few decades.

The optimal design of the rotorblades today is a complex and multifaceted task that requires optimization of material properties, performance, and economy. Given the recent focus on environmental and ecological issues, including the increasing concern over limited resources, the use of wood-plastic composites is especially relevant today. Particularly, their application in resource demanding construction projects such as that of large rotorblades.

Rotorblades:

Rotorblades probably present the most challenging materials, design, and engineering problems. Construction of solid airfoil designs requires inflexible materials such as metals or composites (Hau, 2005). Wood and canvas sails were used on early windmills due to their cost effectiveness, availability, and ease of manufacture and smaller blades can be made from light metals such as aluminium. However, these materials require frequent maintenance.

New wind turbine designs push power generation from the single megawatt range to upwards of 10 megawatts using increasingly larger blades. A larger area effectively increases the tip-speed ratio of a turbine at a given wind speed. Computer aided engineering software such as HyperSizer (originally developed for spacecraft design) can be used to improve blade designs (Collier & Ashwill, 2011) (Collier C. S., 2010).

The shape of a rotorblade in cross section is shown in Figure 2-2. The aerodynamic contours are formed by the (outer) relatively thin shells. They are supported structurally by a longitudinal beam or by webs, which carry a substantial part of the load on the blade. In the longitudinal direction, the rotorblades are tapered and twisted. The tapering is required in order to economize the weight of the material as the load of the cantilever structure increases form tip to root.

Loads on rotorblades:

The rotor and the rotorblades are exposed to external loads. These originate from the wind and from gravity. As the blades are exposed to the wind, the lifting forces on the aerodynamic profile of the blade cause the flap-wise bending on rotorblades. The loads are both static, causing a permanent bending on blades, and dynamic, causing a fatigue flapwise bending. In addition, these static and fatigue loads spectra vary during rotation, as seen by a given blade, when the blade points upwards and downwards. This is caused by the natural wind shear, which is the increase in average wind speed with increasing height over the terrain (Brandsted, Lilholt, & Lystruo, 2005).

Normally, the maximum wind speed for operation of a wind turbine is about 25 m/s. Beyond this speed the rotor is brought to a standstill by turning the rotorblades out of the wind. This position causes the blade to bend due to the steady load on its surface. The natural variation in wind speed will cause a dynamic flap-wise fatigue load spectra.

FINITE ELEMENT MODELLING:

In this chapter the computer modelling aspects of the project are explained. The aim of the computer modelling is to provide a learning library for the Artificial Neural Networks in order to obtain the optimum material constants. The elastic and hyperelastic behaviour of the membranes are modelled using the finite element package, Abaqus. A membrane with the same boundary conditions as the experiments is designed in Abaqus and the pressure values from the experiments are used to measure the deformation of the membrane. At the end of this chapter, the stress distribution in the membrane under the pressure, and the values of von Mises principal stresses are provided.

Preparation:

After gathering the experimental results using the bubble inflation technique, the next step in material characterization is to perform a number of computer simulations. For the purpose of finite element modelling, three classes of materials have been selected: HDPE and WPCs with 30 and 60wt% of wood fibre. These three classes of materials represent both extremes and the average class, concerning the percentage of wood fibre. The simulations are carried out at three different temperatures: — 50°C, 0°C, and 50°C.

Simulation approach:

In this project, Abaqus is used for the computer modelling and finite element analysis. Abaqus is used in the automotive, aerospace, and industrial products industries. The product is popular with academic and research institutions due to the wide material modelling capability, and the program’s ability to be customized.

CONCLUSIONS:

An original experimental setup was designed and developed in CIGELE laboratory at University of Quebec at Chicoutimi. The test setup is to model the bubble inflation technique and it was installed inside an environmental test chamber to carry out experiments at cold temperatures.

|

Table des matières

CHAPTER 1 INTRODUCTION

1.1 Overview

1.2 Problem description

1.3 Research objectives

1.3.1 General objective

1.3.2 Specific objectives

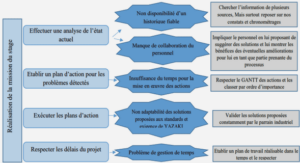

1.4 Methodology

1.5 Statement of originality and contribution to knowledge

1.6 Thesis outline

CHAPTER 2 LITERATURE REVIEW

2.1 Introduction

2.2 Wood-plastic composites

2.3 Wind turbines

2.3.1 Wind energy

2.3.2 Rotorblades

2.3.3 Loads on rotorblades

2.3.4 Material requirements

2.4 Materials for rotorblades

2.4.1 Fibres

2.4.2 Glass and carbon fibre composites

2.5 Manufacturing rotorblades

2.6 Mechanical behaviour of materials

2.6.1 Elastic materials

2.6.2 Hyperelastic materials

2.7 Artificial Neural Networks

2.8 Conclusion

CHAPTER 3 EXPERIMENTAL MODELLING

3.1 Introduction

3.2 Material preparation

3.3 Selection of the experimental approach

3.4 Experimental setup

3.5 Parts of setup

3.5.1 The cylinder

3.5.2 The environmental test chamber

3.5.3 The measuring unit

3.5.4 Data acquisition system

3.6 Mathematical modelling of the experiments

3.7 Conducting an experiment

3.8 Results and discussion

3.9 Conclusion

CHAPTER 4 FINITE ELEMENT MODELLING

4.1 Introduction

4.2 Preparation

4.3 Simulation approach

4.4 Elastic simulation

4.5 Hyperelastic simulation

4.6 Principal stresses

4.7 Conclusion

CHAPTER 5 NEURAL NETWORKS APPLICATION

5.1 Introduction

5.2 Neural networks versus conventional computers

5.3 Human and artificial neurons

5.4 Engineering approach

5.4.1 A simple neuron

5.4.2 Firing rules

5.5 Architecture of neural networks

5.5.1 Feed-forward networks

5.5.2 Feedback networks

5.5.3 Network layers

5.5.4 Perceptrons

5.6 The learning process

5.6.1 Transfer function

5.6.2 The back propagation algorithm

5.7 Artificial Neural Networks application

5.8 WPCs application in rotorblades

5.9 Conclusion

CHAPTER 6 RESULTS VERIFICATION AND ANALYSIS

6.1 Introduction

6.2 Verification Experiments

6.3 Verification modelling

6.4 Effect of Humidity

6.5 Effect of icing on wind turbine fatigue loads

6.5.1 Icing

6.5.2 Precipitation icing

6.5.3 In-cloud icing

6.5.4 Estimation of the ice accretion

6.5.5 Rotorblade icing

6.5.6 Fatigue loads

6.6 Conclusion

CHAPTER 7 CONCLUSIONS

![]() Télécharger le rapport complet

Télécharger le rapport complet