Les bio-aérogels pour l’isolation thermique

Afin de réduire les pertes en énergie, de nombreuses études ont été menées afin de concevoir des bâtiments à basse consommation d’énergie, principalement via l’isolation thermique des murs grâce à l’application de matériaux isolants épais et/ou multicouches. De par leurs caractéristiques physiques exceptionnelles, les aérogels présentent une très faible conductivité thermique, généralement dans le domaine de la super-isolation (c’est-à-dire avec une conductivité thermique inférieure à celle de l’air), et se prêtent donc parfaitement à des applications d’isolation thermique. Les aérogels « classiques » présentent cependant soit de faibles propriétés mécaniques (aérogels de silice), soit leurs procédés de fabrication intègrent des composés toxiques (aérogels organiques). Une alternative prometteuse, alliant hautes performances des matériaux et aspects écologiques, consiste à développer une nouvelle génération d’aérogels super-isolants, biosourcés et issus de procédés plus « verts « , et présentant de propriétés mécaniques satisfaisantes. Le développement de bio-aérogels à base de polymères naturels aux propriétés thermiques super-isolantes est un sujet de recherche d’actualité. (voir par exemple les travaux de Rudaz et al., 2014). Les premiers bio-aérogels à base de cellulose (et dérivés) n’ont pas fait preuve de propriétés super-isolantes (voir, par exemple (Rudaz, 2013)) contrairement aux aérogels de pectine (Rudaz et al, 2014), de cellulose nano-fibrillée (Jiménez Saelices, Seantier, Cathala, & Grohens, 2017 ; Kobayashi, Saito, & Isogai, 2014 ; Seantier, Bendahou, Bendahou, Grohens, & Kaddami, 2016), d’alginate (Gurikov, Raman, Weinrich, Fricke, & Smirnova, 2015) et d’amidon (Druel, Bardl, Vorwerg, & Budtova, 2017). Néanmoins, les relations entre la conductivité thermique, les caractéristiques structurales et les propriétés des bio-aérogels demeurent encore largement méconnues.

Les bio-aérogels pour les sciences du vivant

Les hydrogels sont constitués d’un réseau 3D de polymères interconnectés maintenant une phase aqueuse liquide en leur sein. Leur utilisation est devenue très populaire dans les sciences du vivant du fait de leurs multiples propriétés attractives telles que leur forte teneur en eau, leur capacité de gonflement/contraction, leur perméabilité permettant la diffusion de liquides et molécules (absorption et relargage), la capacité à encapsuler des composés actifs, ou enfin une flexibilité et consistance souple se rapprochant des tissus physiologiques vivants. De ce fait, les hydrogels sont couramment utilisés pour diverses applications et dans de nombreux domaines tels que les industries alimentaire (additifs alimentaires et modificateurs de viscosité), cosmétique (masque facial, gels…), biomédicale (ingénierie de réparation tissulaire, chirurgie plastique, lentilles de contact, pansements, produits d’hygiène…), pharmaceutique (encapsulation et distribution de médicaments), agricole ou environnementale (rétention d’eau, systèmes de distribution des pesticides, adsorption de polluants) (Popa et Volf, 2018). Cependant, les hydrogels présentent quelques inconvénients techniques qui restreignent leurs possibilités d’usage en tant matrices déjà préfabriquées (Caló & Khutoryanskiy, 2015 ; Zhao et al., 2015). Les hydrogels étant des systèmes mécaniquement faibles, ils sont généralement fragiles et difficiles à manipuler. De plus, leur usage est limité en termes de transport (sans rupture du gel) mais également en termes de stockage dans le temps (stabilité microbiologique). Pour pallier la fragilité intrinsèque des hydrogels, une solution envisageable serait de les sécher pour en obtenir des matériaux poreux secs, comme par exemple des aérogels (par séchage supercritique) ou des cryogels (par lyophilisation). Après séchage, il a été constaté une véritable amélioration des propriétés mécaniques permettant de manipuler et de transporter ces derniers plus facilement (et certainement à moindre coût du fait de leur grande légèreté). Ensuite, à la différence des hydrogels, difficiles à stériliser, les matériaux secs ne requièrent pas d’additifs antimicrobiens pour assurer leur stabilité en vue d’un stockage à long terme. Enfin,comme il sera démontré dans ce manuscrit, non seulement le recours au séchage supercritique préserve les propriétés physico-chimiques et fonctionnelles des hydrogels « initiaux », mais peut aussi permettre de mieux contrôler la libération des médicaments quand les aérogels sont utilisés en tant que matrices de libération de médicaments comparativement aux hydrogels.

Sources and extraction of pectin

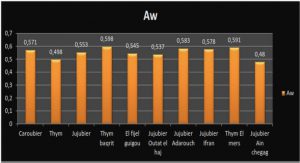

Pectin is a structural polysaccharide present in the middle lamella, the primary and secondary cell walls of non-woody plants, allowing cell wall expansion during plant growth and rigidity of plant tissue (F. Voragen, Schols, & Visser, 2013). Due to their anionic nature, pectins also play a role in the regulation of ion transport and water holding capacity (A. G. J. Voragen, Coenen, Verhoef, & Schols, 2009). Pectin content and chemical structure highly differ depending on plant type, age and source, but commercial pectins are mainly extracted from citrus peel (25 – 30% of dry matter or apple pomace (15 – 18 % of dry matter) (Walter, 2012) and are widely used in food industry as thickening and gelling agent. Sugar beets,sunflower heads and mango are pectin alternative sources, but with lower gelling abilities (BeMiller & Whistler, 2012). Pectin is obtained by hot acid extraction (~ pH 2.0) from the raw vegetal material (apple pomace, citrus peel). The liquid pectin extract is filtered to eliminate solid residues and purified. Pectin extracts are then concentrated under vacuum before being precipitated using alcohols or aluminum salts. Pectin is then pressed and washed after being dried and grounded into powder. These processes lead to commercial High Methylation (HM) pectins of around 70% esterification, additional demethylation treatments are needed to produce other types of pectin (May, 1990).

Physico-chemical properties of pectins

Pectin is water-soluble polyelectrolyte polysaccharide with pKa around 2.9 – 3.5 (Ralet, Bonnin, & Thibault, 2002; Ralet, Dronnet, Buchholt, & Thibault, 2001) depending on pectin DE. Pectins are relatively stable in water at pH ~ 3 – 4, however prolonged heating in a strongly acidic media may lead to pectin degradation by acid hydrolysis, while neutral to alkaline conditions can lead to β-depolymerization and de-methoxylation (I Fraeye et al., 2007; Krall & McFeeters, 1998; Renard & Thibault, 1996). As a consequence of their polyelectrolyte nature, pectins present a high sensitivity to ionization/protonation of carboxyl functions induced by pH change. This is known to strongly impact their chain charge density, their water binding capacity and chains interactions abilities. Dissolved pectin can interact in aqueous solvent by joining their homogalacturonan domains into intermolecular junction zones involving successive physical bonds. These physical bonds can be based on different chains interactions depending on the conditions: chain entanglements, hydrogen bonds, hydrophobic interactions or ionic bonds with multivalent cations. If the number of efficient interactions is sufficient, pectin 3D-network is formed within the aqueous phase, resulting in a physical gel. Pectin solution viscosity and ability to gel are governed by chains interactions, the latter being influenced by various external parameters (e.g. temperature,polymer concentration, soluble solids content, pH and presence of ions, the ionic strength and type of ions, etc.) as well as a large number of pectin intrinsic characteristics (e.g. chemical structure, molecular weight, degree of esterification / amidation / acetylation, branching degree, charge distribution along the chain, etc.) (Axelos & Thibault, 1991; Thakur et al., 1997). Depending on the main type of chains interactions involved in the gelation process, two different physical gelation mechanisms are reported for pectin: acid induced gelation (or “acid gelation”) in acidic media (pH < 3.0) or ionic gelation in the presence of polyvalent cations.

Ionic gelation in presence of divalent cations (called ionic gelation)

Pectin ionic gelation is based on electrostatic interactions involving ionized carboxylates of pectin galacturonic acids units and added metal ions. This gelling mechanism is generally attributed to LM pectin gels due to a higher proportion of non-methylated Gal.A able to interact with cations when dissociated, as compared to HM pectins ((Gilsenan et al., 2000; Löfgren, Walkenström, & Hermansson, 2002; Lootens et al., 2003; Morris, Gidley, Murray, Powell, & Rees, 1980). The cross-linking formed by ionic bonds between carboxylate functions and polyvalent cations such as calcium produce strong, brittle and less elastic pectin gels than those formed by hydrogen and hydrophobic interactions in acidic condition (Sriamornsak, 2003; Ström et al., 2007). The ability of pectin to form complexes with polyvalent cations is based on strong electrostatic interactions between the cations and the free dissociated carboxyl groups of pectin, i.e. at pH close to or higher than pKa (~ 2.9 -3.5). More precisely, the ionic bonding results from specific non-covalent electrostatic interactions between polyvalent cations and the oxygen atoms of the hydroxyl groups, the oxygen atoms of the glucosidic ring and the bridging oxygen atoms of dissociated galacturonic acids through their free-electron pairs (Rudolf Kohn, 1987) as shown in Figure 6a. This leads to the formation of an ionic “egg box” cavity and gives rise to a cross-linking of two different chains in close proximity. The lifetime of the ionic junction depends on the strength of the electrostatic bonds and becomes more stable in the presence of 7 to 20 consecutive ionic cross-links (Braccini & Pérez, 2001; Powell, Morris, Gidley, & Rees, 1982). Successive ionic bonds can form junction zones only between unbranched non-esterified galacturonan segments of two pectin chains in a twofold helical conformation, retaining metal ions in between.

Cellulose II aerogels

Cellulose aerogels are the most studied bio-aerogels (Aaltonen & Jauhiainen, 2009; Gavillon & Budtova, 2008; Liebner, Potthast, Rosenau, Haimer, & Wendland, 2008; Rege, Schestakow, Karadagli, Ratke, & Itskov, 2016; Sescousse et al., 2011; Tsioptsias, Stefopoulos, Kokkinomalis, Papadopoulou, & Panayiotou, 2008). As mentioned above, they can be prepared either from a cellulose solution by dissolution of pulps or of micro-crystalline cellulose resulting in aerogels based on cellulose II such as in (Aaltonen & Jauhiainen, 2009; Hoepfner, Ratke, & Milow, 2008; Innerlohinger et al., 2006; Rege et al., 2016), or from a suspension of nanocellulose particles or fibers (i.e. nanofibrillated cellulose and cellulose nanocrystals such as in (Carlsson et al., 2012; Heath & Thielemans, 2010; Jin et al., 2011; Olsson et al., 2010; Sehaqui, Zhou, & Berglund, 2011)). In this section, we will only present the case of cellulose aerogels obtained from dissolved cellulose. Cellulose is the most abundant organic polymer on earth. It is a linear carbohydrate polymer made of repeated D-glucose bounded by β(1-4) glycosidic bounds. Its general formulais (C6(H10O)5)n, with n the degree of polymerization. It is a structural polysaccharide and the major component of cell walls of plants. Cellulose can be extracted from various lignocellulosic sources (such as cotton linters, wood, flax, hemp…etc.) but can be produced as well by bacteria (Acetobacter xylinum) and also by marine invertebrate animal tunicate. The origin of cellulose and the extraction mode have a strong influence on the purity of cellulose (potential presence of lignin and hemicellulose) and degree of polymerization and thus on its physical-chemical properties. Cellulose is usually organized in a semi-crystalline structure with low ordered amorphous region coexisting with crystalline regions, due to numerous intra- and intermolecular hydrogen bonds between hydroxyl groups (Itagaki, Tokai, & Kondo, 1997). This also impact cellulose physico-chemical properties and its solubility. Cellulose II aerogels are prepared through dissolution-solvent-exchange-supercritical drying route. Different solvents can be used to dissolve cellulose such as N-Methylmorpholine N-oxide (NMMO) monohydrate, NaOH-water (with or without additives), ionic liquids (e.g. 1- Ethyl-3-methylimidazolium acetate (EmimAc), 1-Allyl-3-methylimidazolium chloride (AMIMCl), 1-Butyl-3-methylimidazolium chloride (BMIMCl) …), molten salt hydrates such as zinc chloride (ZnCl2∙6H2O) and calcium thiocyanate, Ca(SCN)2∙6H2O , etc. After the dissolution, non-solvents are used to coagulate cellulose (sometimes called “regeneration” for historical reasons) including water, acids, ethanol, propanol, butanol and acetone. The type of solvent and non-solvent may have a strong impact on the final structural properties of the obtained cellulose II aerogel. In general, two types of network morphologies can be distinguished, either more “fibrous-like” (Figure 24a) and “globular-like” (Figure 24 b, c).

Alginate aerogels

Alginate is produced by brown algae and consists of a copolymer of 1,4-β -D-mannuronic acid and α-L-guluronic acid of various ratios and sequences. Similarly to pectin, alginate can undergo ionic gelation by crosslinking with multivalent cations following the egg-box model or by physical acid-gelation via hydrogen bonds at pH lower than pKa (~3.4 – 3.7) (Dumitriu, 2004). Alginate aerogels were widely studied the past decade due to the “easy” ionic gelation process which allows shaping of alginate gels and aerogels as beads (Alnaief, Alzaitoun, García-González, & Smirnova, 2011; Deze, Papageorgiou, Favvas, & Katsaros, 2012; Silva,Ribeiro, Ferreira, & Veiga, 2006) or monoliths (Mehling et al., 2009). In most of the cases, alginate aerogels were obtained via ionic gelation using different cations (generally Ca2+ but also Zn2+, Ba2+) (Escudero, Robitzer, Renzo, & Quignard, 2009; Tkalec, Knez, et al., 2016; Trens, Valentin, & Quignard, n.d.), or, more rarely, by physical gelation via hydrogen bonds at pH lower than pKa (~3.4 – 3.7) (White, Antonio, et al., 2010). The structure of alginate gel and aerogel was found to depend on cation concentration in alginate solution and the guluronate/mannuronate (C. A. García-González et al., 2011; Ingar Draget, Østgaard, & Smidsrød, 1990; Quignard et al., 2008; Subrahmanyam, Gurikov, Dieringer, Sun, & Smirnova, 2015) . Alternatively, alginate aerogels were also produced via non-solvent phase separation process (without gelation step) (Tkalec et al., 2015b; Tkalec, Kranvogl, Uzunalić, Knez, & Novak, 2016). Alginate aerogels present very attractive structural properties close to synthetic polymer aerogels: homogeneous network morphology, high specific surface area (usually between 350 to 700 m²/g) and variable bulk density (usually from 0.05 to 0.2 g/cm3) depending on alginate concentration and the way and parameters of wet network formation (i.e. acid gelation, ionic gelation, non-solvent phase separation) (Alnaief et al., 2011; Mehling et al., 2009; Quignard et al., 2008; Robitzer et al., 2008; Robitzer, Renzo, & Quignard, 2011; Trens et al., n.d.). Finally, in the work of Gurikov et al. alginate aerogels were reported to present thermal super-insulating properties (P. Gurikov et al., 2015).

Fourier Transformed Infrared spectroscopy (FTIR)

FTIR spectroscopy is based on the interaction of infrared radiation with the matter. When excited by infrared beam, the molecules absorb at specific resonant frequencies that are characteristic to their own structure in relation with the mass of the atoms and the strength of the bond. In practice, a beam of infrared light is passing through the sample, and a then a transmittance or absorbance spectrum as a function of frequency is generated. The chemical structure of the sample can be identified by analyzing the characteristic absorption bands (in terms of intensity and frequency) as they are specifically related to functional groups. FTIR spectroscopy was carried out on a Bruker Tensor 27 spectrometer in PERSEE (Mines ParisTech) with OPUS 7.8 software. Pectin powders were analyzed in attenuated total reflectance mode (ATR) using a Pike MIRacle accessory equipped with a Ge crystal (Pike Technology). The spectrum has been collected 100 times with a resolution of 4 cm-1 corrections for CO2 and H2O were applied to correct the background noise. A smoothing curve treatment and offset correction were applied. Baseline was corrected and set at 1900 cm-1.

|

Table des matières

ABBREVIATIONS AND SYMBOLS

GENERAL INTRODUCTION

ARTICLES AND COMMUNICATIONS

RESUME DES TRAVAUX DE THESE

CHAPTER I. STATE OF THE ART

INTRODUCTION

1. PECTIN: STRUCTURE AND PROPERTIES

1.1. SOURCES AND EXTRACTION OF PECTIN

1.2. CHEMICAL AND MACROMOLECULAR STRUCTURES

1.3. PHYSICO-CHEMICAL PROPERTIES OF PECTINS

1.3.1. Physical acid-gelation

1.3.2. Ionic gelation in presence of divalent cations (called ionic gelation)

1.3.3. Food and pharmaceutical uses of pectin

1.4. CONCLUSION ON PECTIN

2. AEROGELS

2.1. GENERALITIES ON AEROGELS

2.1.1. Network formation via sol-gel route

2.1.2. General aspects of the drying methods

2.2. CLASSICAL INORGANIC AND SYNTHETIC POLYMER AEROGELS: A BRIEF OVERVIEW

2.2.1. First generation of aerogels: silica aerogels

▪ The synthesis of silica aerogels

▪ Hydrophobization treatment

2.2.2. Synthetic organic polymers aerogels

2.2.3. Applications of classical aerogels

2.3. BIO-AEROGELS: THE THIRD GENERATION OF AEROGELS

2.3.1. Synthesis routes of bio-aerogels: similarities and differences with inorganic and synthetic polymer aerogels

▪ Network formation by polymer gelation or by direct coagulation

▪ Solvent exchange and supercritical drying

2.3.2. Aerogels based on neutral polysaccharides

▪ Cellulose II aerogels

▪ Starch aerogels

2.3.3. Aerogels based on polyelectrolyte polysaccharides

▪ Pectin aerogels

▪ Alginate aerogels

▪ Chitosan aerogels

2.3.4. From bio-polymers to the diversity of bio-aerogels

2.3.5. Modifications of bio-based aerogels

2.4. BIO-AEROGELS FOR THERMAL INSULATION APPLICATIONS

2.4.1. Context

2.4.2. Thermal conductivity of aerogels

2.4.3. Aerogels used as thermal insulating materials: issues and open questions

2.5. THE USE OF BIO-AEROGELS AND SILICA AEROGELS FOR DRUG DELIVERY APPLICATIONS

2.5.1. Drug delivery systems: introductive concepts and principles

▪ Modified drug release behaviors

▪ Drug release mechanisms from polymer matrix systems

2.5.2. Aerogels used as drug delivery systems

▪ Production of drug loaded aerogels

▪ Factors influencing drug loading

▪ Case studies of silica-based and polysaccharide-based aerogels

➢ Effect of aerogel composition on the release properties

➢ Effect of preparation conditions on aerogels’ release properties

➢ Effect of hydrophobization on aerogels release properties

➢ Creation of complex matrix systems by production of composite aerogels

CONCLUSIONS

REFERENCES

CHAPTER II. MATERIALS AND METHODS

INTRODUCTION

1. STARTING MATERIALS

1.1. PECTINS

1.2. CELLULOSE

1.3. SILICA-SOLS

1.4. SOLVENTS AND OTHER CHEMICALS

1.4.1. Solvents for aerogels preparation

1.4.2. Chemicals and preparations specific to drug release experiments

2. METHODS

2.1. PREPARATION OF PECTIN AEROGELS

2.1.1. Pectin dissolution

2.1.2. Solvent-exchange step

2.1.3. Supercritical drying using CO2

2.1.4. Alternative drying methods

▪ Freeze drying

▪ Evaporative drying

2.2. CHARACTERIZATION METHODS

2.2.1. Viscometry

2.2.2. Rheology

2.2.3. Fourier Transformed Infrared spectroscopy (FTIR)

2.2.4. Sample shrinkage and aerogel apparent density

2.2.5. Porosity and pore specific volume

2.2.6. Specific surface area measurement (BET method)

2.2.7. Scanning electron microscopy

2.2.8. ESD analysis

2.2.9. Contact angle

2.2.10. Uniaxial compression measurements

2.2.11. Thermal conductivity

2.3. PREPARATION AND CHARACTERIZATION OF DRUG-LOADED PECTIN AEROGELS

2.3.1. Drug incorporation into pectin matrices

▪ Loading of theophylline into aerogels, xerogels and cryogels

2.3.2. Aerogels’ drug loading capacity and specific loading

2.3.3. Determination of the crystalline form of theophylline incorporated into pectin matrices by X-ray diffraction

2.3.4. In vitro drug release experiments

▪ Determination of theophylline absorbance properties

▪ In vitro drug release experiments

2.3.5. Cytoxocity profile of different solid matrices

▪ Sample preparation

▪ MTS assay method

REFERENCES

CHAPTER III. TUNING STRUCTURE AND PROPERTIES OF PECTIN AEROGELS

INTRODUCTION: IMPORTANCE OF AEROGELS’ STRUCTURAL PROPERTIES

1. CHARACTERIZATION OF PECTINS

1.1. CHARACTERIZATION OF PECTINS’ DEGREE OF ESTERIFICATION

1.2. DETERMINATION OF PECTIN MOLECULAR WEIGHTS

2. TUNING STRUCTURE AND PROPERTIES OF LOW METHYLATED PECTIN AEROGELS

2.1. INFLUENCE OF NON-SOLVENT TYPE AND PECTIN P35 CONCENTRATION ON AEROGEL STRUCTURE AND PROPERTIES

2.2. INFLUENCE OF PH ON LOW-METHYLATED PECTIN AEROGEL STRUCTURE AND PROPERTIES

2.3. EFFECT OF CALCIUM IONS ON LOW-METHYLATED PECTIN AEROGEL STRUCTURE AND PROPERTIES

2.4. EFFECT OF MONOVALENT IONS (NACL) ON LOW-METHYLATED PECTIN AEROGEL STRUCTURE AND PROPERTIES

2.5. DISCUSSION ON THE CORRELATIONS BETWEEN THE PROCESSING PARAMETERS AND THE AEROPECTIN PHYSICAL PROPERTIES

2.6. MECHANICAL PROPERTIES OF LOW-METHYLATED PECTIN AEROGELS

2.6.1. Effect of pectin concentration

2.6.2. Effect of pH of starting pectin solution on the mechanical properties

2.6.3. Effect of addition of calcium into pectin solution

2.7. CONCLUSIONS ON THE PROPERTIES OF LOW-METHYLATED PECTIN AEROGELS

3. EFFECTS OF PECTIN DEGREE OF ESTERIFICATION ON PECTIN AEROGELS STRUCTURAL PROPERTIES

3.1. IMPACT OF DE ON AEROPECTIN STRUCTURAL PROPERTIES VARYING THE PH

3.1.1. Impact of pectin DE on the viscosity of pectin solutions while varying the pH

3.1.2. Impact of pectin DE on aeropectin properties while varying the pH

3.2. IMPACT OF DE ON AEROPECTIN STRUCTURAL PROPERTIES VARYING R(CA) RATIO

3.2.1. Effect of DE on gel state at different R(Ca)

3.2.2. Effect of pH on calcium sensitivity for various DE

3.3. CONCLUSIONS ON THE INFLUENCE OF PECTIN DE ON AEROPECTINS PROPERTIES

CONCLUSIONS

REFERENCES

CHAPTER IV. THERMAL CONDUCTIVITY-STRUCTURE PROPERTIES CORRELATIONS OF PECTIN AEROGELS

INTRODUCTION

1. THERMAL CONDUCTIVITY AS A FUNCTION OF PECTIN AEROGEL DENSITY: SUMMARY OF ALL RESULTS

2. INFLUENCE OF PECTIN CONCENTRATION AND NON-SOLVENT TYPE ON AEROGEL THERMAL CONDUCTIVITY

2.1. INFLUENCE OF PECTIN CONCENTRATION

2.2. INFLUENCE OF NON-SOLVENT TYPE ON AEROGEL THERMAL CONDUCTIVITY

3. INFLUENCE OF CA-INDUCED CROSS-LINKING AND PH ON PECTIN AEROGEL PROPERTIES

3.1. INFLUENCE OF PH AT R(CA) = 0 AND 0.2

3.2. INFLUENCE OF CALCIUM CONCENTRATION AT PH 3

CONCLUSIONS

REFERENCES

CHAPTER V. PECTIN AEROGELS AS DRUG DELIVERY SYSTEMS

INTRODUCTION

1. PRODUCTION AND CHARACTERIZATION OF THE DRUG-LOADED AEROPECTINS

1.1. METHOD OF INCORPORATION OF THEOPHYLLINE INTO AEROGEL PRECURSORS

1.2. CHARACTERIZATION OF LOADED AEROPECTINS

1.2.1. Aeropectins drug loading efficiency

1.2.2. Structural characterization of theophylline loaded aeropectins

1.2.3. Determination of crystalline structure of theophylline incorporated in pectin aerogels, xerogels and cryogels by X-rays diffraction

2. STUDY OF THEOPHYLLINE RELEASE FROM PECTIN, AEROGELS, CRYOGELS AND XEROGELS

2.1. STRUCTURAL PROPERTIES OF PECTIN MATRIX MADE WITH DIFFERENT DRYINGS

2.2. THEOPHYLLINE RELEASE PROFILES AS A FUNCTION OF DRYING METHOD

2.3. COMPARISON OF RELEASE PROPERTIES OF PECTIN HYDROGELS AND AEROGELS

3. BACKGROUND ANALYSIS OF AEROPECTIN BEHAVIOUR AND THEOPHYLLINE RELEASE

3.1. INFLUENCE OF PH OF RELEASE MEDIUM ON AEROPECTIN EROSION, SWELLING AND DRUG RELEASE

3.2. SELECTION OF A MODEL TO DESCRIBE RELEASE KINETICS

3.2.1. Mathematical models fitting drug release profiles

3.2.2. Overview of drug release from aeropectins

4. CASE STUDIES: INFLUENCE OF VARIOUS PARAMETERS ON THE KINETICS OF THEOPHYLLINE RELEASE FROM PECTIN AEROGELS

4.1. INFLUENCE OF PH OF PECTIN SOLUTIONS ON RELEASE KINETICS OF THEOPHYLLINE FROM AEROPECTIN

4.2. IMPACT OF CALCIUM CONCENTRATION ON RELEASE KINETICS OF THEOPHYLLINE FROM AEROPECTIN

CONCLUSIONS

REFERENCES

CHAPTER VI. ORGANIC-ORGANIC AND ORGANIC-INORGANIC PECTIN-BASED COMPOSITE AEROGELS FOR DRUG RELEASE APPLICATIONS

INTRODUCTION

1. CELLULOSE-PECTIN COMPOSITE AEROGELS

1.1. PRODUCTION AND CHARACTERIZATION OF CELLULOSE-PECTIN COMPOSITES

1.1.1. Production of cellulose-pectin composites

▪ Production of cellulose matrix samples

▪ Impregnation of cellulose matrix by pectin solution

1.1.2. Structure and properties of cellulose-pectin composite aerogels

▪ Formation of interpenetrated network cellulose-pectin and density of composite aerogels

▪ Morphology of composite aerogels

1.2. CELLULOSE-PECTIN COMPOSITES AS DRUG DELIVERY SYSTEM

1.2.1. Characteristics of drug-loaded composite cellulose-pectin aerogels

1.2.2. Theophylline release profiles from cellulose-pectin aerogels

▪ Comparison of theophylline release from neat reference pectin-based versus neat reference cellulose-based aerogel matrices

▪ Influence of pectin/cellulose composition on release kinetics of theophylline from composite aerogels

➢ Cellulose-pectin composite aerogels without calcium

➢ Cellulose-pectin composite aerogels with calcium

1.3. CONCLUSIONS ON PECTIN-CELLULOSE COMPOSITE AEROGELS

2. PECTIN-SILICA COMPOSITE AEROGELS

2.1. PRODUCTION AND CHARACTERIZATION OF PECTIN-SILICA COMPOSITES

2.1.1. Materials

2.1.2. Sol-gel synthesis of neat silica aerogels using either TEOS or PEDS

▪ Production of silica aerogels made from TEOS

▪ Production of silica aerogels made from PEDS

1.1.1. Production of pectin-silica composite aerogels

▪ Process route of pectin-silica composite aerogels

▪ Calculation of silica diffusion time inside pectin matrix

▪ Estimation of the silica impregnation efficiency into pectin matrices

2.2. CHARACTERIZATION OF PECTIN-SILICA COMPOSITE AEROGELS

2.2.1. Influence of the type of silica sol on the properties of neat silica aerogels (TEOS vs PEDS)

2.2.2. Distribution and impregnation efficiency of silica in pectin matrix

2.2.3. Structural properties of pectin-silica composite aerogels and loading with theophylline

2.2.4. Theophylline loading in pectin-silica composite aerogels

2.3. THEOPHYLLINE RELEASE PROFILES FROM PECTIN-SILICA AEROGEL MATRICES

2.3.1. Comparison of theophylline release from neat silica and pectin aerogels matrices

2.3.2. Theophylline release from pectin-silica composite aerogels

➢ Without calcium crosslinking

➢ Pectin cross-linked with calcium

2.4. CONCLUSIONS ON PECTIN-SILICA COMPOSITE AEROGELS

3. CYTOXOCITY PROFILE OF DIFFERENT AEROGELS AND CRYOGELS MATRICES

CONCLUSIONS

REFERENCES

GENERAL CONCLUSIONS AND PERSPECTIVES

ANNEX. FUNDAMENTALS AND CONCEPTS FOR DRUG DELIVERY APPLICATIONS

1. DRUG RELEASE MECHANISMS FROM POLYMER MATRIX SYSTEMS

1.1. WATER DIFFUSION AND POLYMER RELAXATION (SWELLING)

1.2. MATRIX EROSION

1.3. DRUG DISSOLUTION

1.4. DRUG DIFFUSION

2. MATHEMATICAL MODELS OF RELEASE KINETICS

2.1. ZERO-ORDER KINETICS

2.2. FIRST-ORDER RELEASE KINETICS

2.3. HIGUCHI RELEASE MODEL

2.4. HIXSON-CROWELL RELEASE MODEL

2.5. HOPFENBERG MODEL

2.6. RITGER–KORSMEYER–PEPPAS (POWER LAW) MODEL

2.7. PEPPAS–SAHLIN MODEL

2.8. GALLAGHER–CORRIGAN MODEL

REFERENCES

![]() Télécharger le rapport complet

Télécharger le rapport complet