Goals and challenges ofWind turbine industry

Nowadays, the industry of wind turbines knows a fast progress, with a size turns around 7-8MW. The initiative targeted is to build 10-20 MW wind turbine and to reach an installed capacity cutting the edge of 800 GW by 2020 [19]. Several grid codes have been issued to manage the behavior of wind turbine. In which, even with the unpredictability of climate conditions and the fluctuation of wind speed, wind turbines should behave as a traditionalpower station in terms of power quality [29]. The wind turbine has to be also featured by the to control the delivered active, reactive power and to offer support services for the utility grid characteristic, such as adjusting the frequency and enhancing the voltage profile, etc. [26]. ln addition to that, wind turbine manufacturers are invited to promote new techniques to increase the generated power capacity, reduce the cost of maintenance, improve low voltage ride through capability (LVRT). In this sense, one of the most promising solutions in this area is the use of multiphase generators where the number of phases is more or equal ta six. In the following, we present a survey on the multiphase generator, exactly a dual stator (six phases) induction generator.

Self-excitation dual stator winding induction generator: State-of-the-art on multiphase generator

Due to the high economic yield and with the same reason for preferring multiphase instead of single phase systems for the transportation of power, a new generation of multiphase generators (phases number is more or equal to six) has been strongly emerging especially with the expansion of power electronics field [30]. This category brings a many advantages compared to the traditional three-phase generator. For example, since the number of phases is increased by two-time, also the generated power will be doubled without increasing the current per phase [31]. On the other hand, it also reduces harmonics, rotor losses, and torque ri pp les [23]. Multiphase generator penetrates the wind power generation field in grid-tied and stand-alone topologies. The additional degrees offreedom in multiphase generator allows it to inherit the conventional three-phase generator (such as DFIG) in the medium voltage operation (up to 8 MW), with more flexibility and high fault tolerance [32].

Among multiphase machines, self-excited dual stator winding induction generator (SEDSWIG) have been proposed in many applications [33]. It consists of two identical threephase winding sets which permit building several topologies [30]. Each three-phase winding set forms a stator, where the first one is called in such papers control winding and the second one is called power winding [34]. There is no physical contact between stators, that reduces the propagation of harmonics between them and enhance the electromagnetic compatibility in the power system [30].

ln previous works, researchers proposed topologies in which the control winding (stator 1) is connected to what they called, a static excitation controller (SEC), while the power winding (stator II) used to feed the end user as shown in Figure 1-6. The control winding with the SEC is used to compensate reactive power, to regulate voltage, enhance the frequency and to maintain the excitation of the generator [35] . This topology was proposed in standalone applications to meet the growing power request for the recent trend in wind power, aircraft, ships, automobiles, etc.

ln stand-alone applications, SE-DSWIG has been perfectly used in fixed and variable frequency ac systems, hydro and wind power extraction, as weIl as for simultaneous hybrid DC/AC output voltage supply. For instance, in [36], authors used SE-DSWIG in variable frequency AC application. The power winding set generates an AC power and the control winding set connected to the SEC. This later injects a variable reactive power into the machine to compensate the voltage dips and to stabilize frequency. At the same time, the SEC provides a DC voltage through its DC-bus supply. A control strategy based on the instantaneous slip frequency is applied to the SEC. Experimental results show good stability of voltage and frequency even with variation in load impedance. In [37] , the power winding set feeds an unbalance load while the control winding through the SEC is used to regulate the positive sequence of the power winding set output voltage and current and to eliminate the negative sequences of the unbalanced load. In [35], authors used the same topology presented in Figure 1-7, where they tried to optimize the excitation capacitor with taking into account the generator parameters, prime mover speed, load variation, and the evolution of the wind turbine power curve. ln this case, the SE-DSWIG has been used also for dc voltage application where the SEC acts as a rectifier for charging batteries and feeding dc current load. ln [38], Haijun Xue et al. made a comparison between four control strategies applied on SE-DSWIG for DC power generation. These control strategies are control-winding flux orientation control, control-winding voltage orientation control, control-winding direct power control, and instantaneous slip frequency control. Ali the proposed control strategies proved their capability in dc voltage generation with more superiority for the instantaneous slip frequency control in terms of DC voltage stability. In [39], Feifei Bu et al. proposed an asymmetrical analysis of the SE-DSWIG operating in variable frequency and feeding an unbalanced load. Results show that the SE-DSWIG has a good behavior even in unbalanced load scenario. The negative sequence and harmonic current generated by this fault don’t propagate between stators. In [40] , Kamal Nounou et al. evaluate the performance of the SEDSWIG under variable speed and at different loads. A vector control strategy is built up and applied to the system basing on the method of indirect rotor flux orientation control which brought a good performance for the system. This work [41] , presents a study on SE-DSWIG performance for variable frequency AC generation, feeding a variable capacitive-inductive load. The contribution of this work is established on the proposition of an improved instantaneous slip frequency control strategy applied on the SEC with considering the active and the reactive power consumed by loads. ln [42] , authors investigate the use ofSE-DSWIG to generate DC voltage with both of stators through two rectifiers, using a control technique based on nonlinear input-output linearization. While in [43] , Feifei Bu et al. proposed a 9- phase induction generator operates in very high-speed range. The power winding consists of six phases forming a dual stator, used for the DC voltage generation through two rectifiers.

The DC-buses of both rectifiers are connected in shunt to maintain the DC voltage at an adequate level. The control winding is connected to a SEC which is used to enhance the SE16 DSWIG performance and to charge the battery as depicted in Figure 1-7. The SEC IS controlled using the control-winding-tlux orientation control strategy.

Research Goals

In the literature, the power conversion systems based on SE-DSWIG are used in traditional topologies where the generator is connected to the grid through back-to-back converters. ln addition to that, we did not find a strong study about the ability of maintaining the proposed topologies connected to the grid even at the presence of issues in terms of voltage sag and swell. Hence, the target of this thesis is to propose a new concept of power improvement in wind turbine based SE-DSWIG. The orientation ofthis thesis is twofold: the first one is the use of a dual stator induction generator to increase the generated power by two-time compared to a convention three-phase induction generator, and the second is to propose a new technique for the power quality improvement of a wind turbine in any scenario.

Main objective

The main objective ofthis thesis is highlighted as follows:

• 8ased on the literature, a depth investigation on SE-DSWIG and its advantages compared to the conventional three-phase induction machine was proposed.

• Exploration of a six-phase induction motor for a drive application.

• Design of a passive compensator based inductance and capacitance to ameliorate the performance of SE-DSWIG in a standalone application.

• Investigation on customer power devices (D-ST A TCOM, DVR, UPQC) and their capability to improve the power quality in a wind turbine based SE-DSWIG.

• Design and insertion ofpassive damping LCL filter between customer power devices and the grid, to elimination the penetration of harmonic.

• Low voltage ride through enhancement for the proposed wind turbine based SEDSWIG

• Development of nonlinear and adaptive based sliding mode and fuzzy logic control strategies respectively, to ensure a smooth functioning of the multi-variable system (SEDSWIG, UPQC).

Contribution ofthis thesis

• This work proposes a new topology of wind energy conversion systems based SEDSWIG for grid-connected and standalone applications in the same time. SE-DSWIG is connected to the grid through the first stator and supplying an islanded microgrid through the second stator winding.

• Multi-converter based unified power quality conditioner (MC-UPQc) is connected between the grid/load and the generator to compensate the supply voltage imperfection, enhance voltage and current at the PCC even in the presence of sudden faults, ameliorate the LVRT capability, and synchronize the generator on the same frequency of the grid.

• The proposed MC-UPQC involves three converters connected back to back through an energy storage system, which permits exchanging active power between them.

• Two converters of MC-UPQC are acting as DVR where each one of them is connected through a series injection transformer at the dual stators terminais, while the third converter behaves as a D-STA TCOM and connected in shunt between the grid and the first stator through a passive damping LCL filter.

• Following the challenges entrusted by the MC-UPQC, a cascade sliding mode control technique is applied on D-STATCOM whereas a synchronous reference frame control theory is used to supervise both DVRs.

|

Table des matières

Abstract

Acknowledgements

Table des matières

Liste des tableaux

Liste des figures

List of acronyms

Chaptre 1 – Introduction

1.1 A brief history on the energy

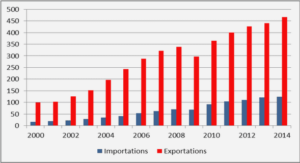

1.2 Renewable resources: Status and Trends

1.2.1 Biomass energy

1.2.2 Geothermal energy

1.2.3 Ocean energy

1.2.4 Hydropower energy

1.2.5 Solar energy

1.2.6 Wind energy

1.3 Main parts ofwind turbine

1.3.1 Power electronic devices in wind turbine

1.3.2 Generator in wind turbine

1.3.2.1 Wound-rotor synchronous generator

1. 3. 2. 2 Permanent synchronous generator

1.3.2.3 Double f ed induction generator

1.3.2.4 Self-excitation induction generator

1.3.3 Goals and challenges of Wind turbine industry

1.3.4 Self-excitation dual stator winding induction generator: Stateof- the-art on multiphase generator

1.4 Research Goals

1.4.1 Main objective

1.4.2 Contribution of this thesis

1.4.3 Publications

1.4.4 Outline ofthesis

Chaptre 2 – Field oriented control of a dual stator winding induction motor with indirect speed regulation method

2.1 Introduction

2.2 Description of the dual stator winding induction motor

2.3 Mathematical modeling of DS WIM in biphase system

2.3.1 Electric equations

2.3.2 Magnetic equations

2.3.3 Power consumption and electromagnetic torque of DSWIM

2.4 Dual stator winding induction motor for variable speed application

2.4.1 DSWIM fed directly from the grid

2.4.2 DSWIM fed by a voltage source inverter with PWM control.31

2.4.2.1 Modelling of voltage source inverter

2.4.2.2 Open loop control of inverters using PWM

2.4.3 Vector control of dual stator winding induction motor

2.4.3.1 Principle of field-oriented vector control technique

2.4.3.2 Indirect vector control with speed regulation

2.5 Numerical simulation and results discussion

2.5.1 Case study #1

2.5.2 Case study# 2

2.5.3 Case study# 3

2.6 Conclusion

Chaptre 3 – Self-Excited-DSWIG for stand-alone application with passive compensator

3.1 Introduction

3.2 Description of SE-DSWIG

3.3 Mathematical modeling of SE-DSWIG

3.3.1 Electric equations

3.3.2 Magnetic equations

3.3.3 Excitation capacity bank model

3.4 Passive compensator

3.4.1 Passive compensator design for voltage sag

3.4.1.1 Shunt compensator design

3.4.1.2 Series compensator design

3.5 Modeling of the end-user

3.5.1 End-user with no-passive compensator

3.5.2 End-user with shunt pass ive compensator

3.5.3 End-user with series passive compensator

3.6 Numerical results and discussion

3.6.1 SE-DSWIG performance at no-Ioad condition

3.6.2 SE-DSWIG performance feeding the end-user in the presence of shunt Pc

3.6.3 SE-DSWIG performance feeding the end-user in the presence of series PC

3.6.4 SE-DSWIG performance with a step change in load impedance

3.6.5 SE-DSWIG performance with a step change in prime mover speed

3.7 Conclusion

Chaptre 4 – Study ofD-STATCOM and DVR for poor power correction, voltage sag and swell mitigation

4.1 Introduction

4.2 Distributed Static Synchronous Compensator (D-STATCOM)

4.2.1 D-STA TCOM configuration

4.2.1.1 Mathematical modeling of the power system with DSTATCOM

4.2.1.2 Phase-Locked-Loop

4.2.2 Design of D-STA TCOM components

4.2.2.1 Estimation of DC-side voltage and capacitor

4.2.2.2 Estimation of the interfacingfilter

4.2.2.3 Frequency response of the power system

4.2.3 D-STATCOM operation and control design

4.2.3.1 SMC application in the inner loop

4.2.3.2 SMC application in the outer loop

4.3 Dynamic Voltage Restorer (DVR)

4.3.1 DVR configuration

4.3.2 Mathematical modeling of the power system with DVR

4.3.3 Design ofDVR components

4.3.3.1 lnjected voltage rating

4.3.3.2 Apparent power of DVR

4.3.3.3 Current rating of DVR

4.3.3.4 DC-side voltage

4.3.3.5 DVR interfacingfilter

4.3.4 DVR operation and control

4.4 D-STA TCOM and DVR performance analysis

4.4.1 Simulation results with D-STA TCOM

4.4.2 Simulation results with DVR

4.5 Conclusion

Chaptre 5 – A Study on the UPQC for power quality improvement

5.1 Introduction

5.2 Topology of the system under study with UPQC

5.2.1 Description of the system under study

5.2.2 Mathematical modeling of the system under study

5.2.3 Phasor diagram ofUPQC

5.3 Control system design

5.3 .1 Control strategy applied on OVR

5.3.2 Control strategy applied on O-STA TCOM

5.3.3 Adaptive fuzzy logic controller design

5.4 UPQC performance analysis

5.4.1 Performance analysis of OVR against voltage sag and swell

5.4.2 Performance of OVR against distorted voltage

5.4.3 Performance analysis of O-STA TCOM against harmonie CUITent

5.4.4 Performance analysis of O-STA TCOM against unbalanced and neutral currents

5.5 Conclusion

Chaptre 6 – Performance improvement of SE-OSWIG using a MC-UPQC

6.1 Introduction

6.2 Compact representation of SE-OS WIG mathematical equations

6.3 System under study with MC-UPQC

6.3.1 Mathematical modeling of the proposed power system

6.3.2 Passive damping LCL filter design

6.4 Control system design

6.4.1 O-STA TCOM control

6.4.1.1 Challenges ofD-STATCOM

6.4.1.2 Cascade sliding mode controller design

6.4.2 Control ofDynamic Voltage Restorer (DVR-I, DVR-II)

6.4.2.1 Estimation of the synchronizing unit vector

6.4.2.2 Description of the SRF Control Theory applied to D VR

6.5 N umeric results and analysis

6.5.1 Characteristics of SE-DSWIG in off-grid and at no-Ioad conditions

6.5.2 SE-DSWIG performance in variable speed with noncompensator

6.5.3 SE-DSWIG performance in variable speed with MC-UPQC

6.5.4 SE-DSWIG performance in standalone application with variable load

6.5.5 SE-OSWIG performance in grid connected conditions

6.5.6 Grid active and reactive power control

6.6 Conclusion

Chaptre 7 – Conclusion

Bibliography

Appendix A – Parameters of dual stator winding induction motor

Appendix B – Parameters of dual stator winding induction generator, passive compensator and the load impedance

Appendix C – Parameters of the system under study with D-STATCOM and DVR

Appendix 0 – Parameters of the system under study with UPQC

Appendix E – Parameters of the system under study with MC-UPQC

Appendix F – Résumé étendu

![]() Télécharger le rapport complet

Télécharger le rapport complet