Alloys are materials having metallic properties and are composed of two or more elements, at least one of which is a metal. In the case of aluminum alloys, most of them contain 90 to 96% aluminum. Aluminum alloys are divided into two categories, wrought alloys and cast alloys. Aluminum casting alloys are used in a large number of applications including automobiles, trucks, transmission of electricity, development of transportation infrastructures, and in the aerospace and defence industries. The fast growth of aluminum alloys in industrial applications is related to their high strength-to-weight ratio which improves the mechanical properties and performance of the products. Among different foundry alloys, aluminum casting alloys are very popular, as they have the highest castability ratings, possess good fluidity and comparably low melting points. Their light weight and high strength-to-weight ratio are the main reasons why cast iron and steel components are being increasingly replaced by aluminum alloys, particularly in the automotive industry. Choosing one casting alloy over another tends to be determined by the relative ability of the alloy to meet one or more of the characteristics required for a specific application.

SURVEY OF THE LITERATURE

Cast Al-Cu Alloys

Copper (Cu) has the single greatest impact of all alloying elements on the strength and hardness of aluminum casting alloys, in both as-cast and heat-treated conditions, and at ambient and elevated service temperatures. Copper improves the machinability of aluminum alloys by increasing the matrix hardness, making it easier to generate small cutting chips and fine machined finishes. On the downside, copper generally reduces the corrosion resistance of aluminum and, in certain alloys and tempers, it increases the stress corrosion susceptibility. Copper is generally used to increase the tensile strength and hardness through heat treatment. It also reduces the resistance to corrosion and hot cracking, or hot tearing.

A variety of alloys with copper as the major addition were developed . Most of these alloys fall within one of the following groups:

• Cast alloys with 5% Cu, often with small amounts of silicon and magnesium.

• Cast alloys with 7-8% Cu, which often contain large amounts of iron and silicon and appreciable amounts of manganese, chromium, zinc, tin, etc.

• Cast alloys with 10-14% Cu. These alloys may contain small amounts of magnesium (0.1-0.3%), iron up to 1.5%, up to 5% Si and smaller amounts of nickel, manganese, chromium.

• Wrought alloys with 5-6% Cu and often small amounts of manganese, silicon, cadmium, bismuth, tin, lithium, vanadium and zirconium. Alloys of this type containing lead, bismuth, and cadmium exhibit superior machinability.

• Dural also called duraluminum (considered as one of the earliest types of agehardenable aluminium alloys), main alloying constituents are copper, manganese, and magnesium, and sometimes with a low-silicon content which is typically less than 12%.

• Copper alloys containing nickel, which can be subdivided in two groups: the Y alloy type, whose basic composition is 4% Cu, 2% Ni, 1.5% Mg; and the Hyduminiums, which usually have lower copper contents and in which iron replaces 30me of the nickel.

n most of the alloys in this group, aluminum is the primary constituent and in the cast alloys the basic structure consists of cored dendrites of aluminum solid solution, with a variety of constituents at the grain boundaries or in the interdendritic spaces, forming a brittle, more or less continuous network of eutectics. Copper forms (CuFe)Al6 and Cu2FeAl7 with iron, and (CuFeMn)Al6 and Cu2Mn3Al20 with manganese. The amount of silicon available to some extent controls the copper compounds formed. Silicon above 1% favors the formation of FeSiAl5 phase, over the iron-copper compounds and (CuFeMn)3Si2Al15. Similarly, but to a lesser extent, the available silicon is affected by iron and manganese contents. With the Cu:Mg ratio below 2 and the Mg:Si ratio well above 1.7 the CuMg4Al6compound is formed, especially if appreciable zinc is present. When Cu:Mg > 2 and Mg:Si > 1.7, CuMgAl2 is formed. If the Mg:Si ratio is approximately 1.7, Mg2Si and CuAl2 are in equilibrium. With the Mg:Si ratio 1 or less, Cu2Mg8Si6Al5, is formed, usually together withCuAl2. When the copper exceeds 5%, commercial heat treatment cannot dissolve it and the network of eutectics does not break up. Thus, in the 10- 15% Cu alloys there is little difference in structure between the as-cast and heat treated alloys. Magnesium can combine with silicon and copper. When appreciable amounts of lead, bismuth or tin are present, Mg2Sn, Mg2Pb, Mg2Bi3 can be formed. Aluminum-copper alloys that do not also contain at least moderate amounts of silicon have relatively poor fluidity and resistance to hot tearing during solidification. Adding Cu lowers the melting point of aluminum at the eutectic temperature, reaching maximum solid solubility in the binary alloy.

HOT TEARING

Hot tearing is one of the major problems of casting technology, and has been investigated since the beginning of the 20th century. In 1936, Verö presented his study of the hot shortness of aluminum alloys and reported that hot tearing was caused during solidification of the alloy because of the stress developed from the contraction of the primary phase. In the first stage of solidification, a coherent network has not yet formed, and thus hot tears would not occur. During growth of the dendrites, the coherent network forms. Further solidification would produce stress when the alloy contraction is restrained by the mold. If the remaining eutectic liquid is sufficient, it would feed the incipient tears. Eskin and Pumphrey et al. reported that even though the strength of the metal increases with decreasing solidification temperatures, hot tears still could develop as long as a small amount of residual liquid remained.

ROLE OF ALLOYING ELEMENTS

The role of the addition of alloying elements on the properties of materials is well documented in the literature. In the following subsections, the alloying elements used in this study, their characteristics and their effects on aluminum alloys will be presented.

Zirconium and Scandium

Zirconium (Zr) is a lustrous, grey-white, soft and malleable metal which is solid at room temperature, and highly corrosion resistant. It is added to increase the strength of aluminum alloys, based on the production of precipitates in the form of primary intermetallic particles of Al3Zr. Zirconium is also used in a wide selection of aluminum alloys to control the microstructure and mechanical properties. It has the smallest diffusion flux in aluminum of all the transition metals. Zirconium atoms have a high binding energy with the vacancies of aluminum. The Al3Zr particles are resistant to dissolution and coarsening, and control the evolution of the grain and sub-grain structure, thus providing the means to enhance and maintain the alloy strength and ductility in the precipitationhardened T6 condition or during subsequent processing operations.

Titanium

The melting point of the pure titanium (Ti) is 1668 °C (3034 °F), in solid state the titanium alloys are either hexagonal close-packed (α) or body-centered cubic (β) structure. Pure titanium undergoes an allotropic transformation from hexagonal close-packed (HCP) alpha titanium to body-centered cubic (BCC) beta titanium as its temperature is raised through 882 °C (1620 °F). Titanium is added individually or in combination with boron (B) is used to refine the grain structure of α-Al, as it creates many nuclei in the melt, which encourage the formation of small equiaxed grains of α-Al, which otherwise solidifies with a coarse, columnar grain structure. Titanium as a grain refiner is very effective in reducing the grain size.

The titanium-aluminum binary system provides a model for solution strengthening. In addition to that, it is the prototype of technical α alloys, as well as the components of α + β alloys.

CONCLUSION

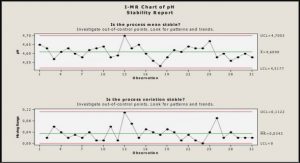

The present study was carried out to investigate the effects of Sr, Ti, Zr, Sc and Ag additions, individually or in combination, on the performance of an Al-2%Cu based alloy. Using different combinations/amounts of these additives, thirteen alloys were prepared (base alloy A and alloys B through M). From the microstructural observations and a statistical analysis of the hardness and tensile test data and quality charts constructed from the latter, the following conclusions may be drawn.

|

Table des matières

CHAPTER 1 DEFINING THE PROBLEM

1.1 INTODUCTION

1.2 OBJECTIVES

CHAPTER 2 SURVEY OF THE LITERATURE

2.1 CAST ALUMINUM ALLOYS

2.2 HOT TEARING

2.3 ROLE OF ALLOYING ELEMENTS

2.4 INTERMETALLIC PHASES

2.5 QUALITY INDEX (Q)

2.6 CASTING TECHNIQUES

CHAPTER 3 EXPERIMENTAL PROCEDURES

3.1 INTODUCTION

3.2 ALLOY PREPARATION AND MELTING PROCEDURES

3.3 CASTING PROCEDURES

3.4 HEAT TREATMENT PROCEDURES

3.5 METALLOGRAPHY

3.6 MECHANICAL TESTING

CHAPTER 4 RESULTS AND DISCUSSION

4.1 INTRODUCTION

4.2 MICROSTRUCTURAL EXAMINATION

4.3 EFFECTS OF ADDITIVES ON THE HARDNESS AND TENSILE

PROPERTIES

4.3.1 Hardness Test Results

4.3.2 Tensile Test Results

4.4 ANALYSIS OF TENSILE PROPERTIES USING THE QUALITY INDEX

CONCEPT

4.5 STATISTICAL ANALYSIS

CHAPTER 5 CONCLUSION

![]() Télécharger le rapport complet

Télécharger le rapport complet