Anode raw materials

Coke :One of the raw materials of carbon anodes is calcined petroleum coke, which is produced from the heavy residual fractions of crude oil. The source of crude oil, processes within the refinery, and calcination conditions determine its quality and composition. The calcined coke contains different impurities such as sulfur and metals including Ni, V, and Fe. In recent years, the impurity content of the coke has increased .

Butts :Butts are the remaining section of the anode after electrolysis. They contain large amounts of sodium coming from the electrolytic bath. Butts are cleaned and recycled .

Recycled anodes :Recycled anodes are usually generated from start-up and shutdown operations, process variations and reject formed during anode manufacturing. Green recycled anodes can have different pitch contents. The baked recycled anode is usually processed with the butt fraction .

Pitch :The role of binder pitch is to cover the coke particle surface, penetrate into the pores, and fill the void space between the particles. During baking, pitch carbonizes and binds the particles together. Good wetting of coke by pitch helps better coat and bind coke particles and improves the filling of the pores. Pitch is obtained as a residue during the distillation of coal tar in a coke oven at about 1100 °C. The chemical compounds in pitch have a broad molecular weight distribution .

Different methods to estimate Fe, Ni, and V

Inductively Coupled Plasma Spectrometry

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) is widely used in the determination of impurities in crude oil, fuel oil, naphtha, residual oil, asphalt, and coke.

The method is also used in the analysis of monomers, natural gas, and oil products . Another report describes the determination of vanadium in petroleum and petroleum products using ICP-MS techniques . Inductively Coupled Plasma Atomic Emission Spectroscopy (ICP-AES) was used to measure the catalytic performance of NiMo catalysts supported on tailored activated carbon (AC) .

X-ray Fluorescence Spectroscopy (XRF)

Verma described the application of X-ray Fluorescence (XRF) technique in the fields of industry, medicine, biology, environmental studies, archaeology, and geology.Atomic Absorption Spectrometry (AAS).

Some researchers used atomic fluorescence spectrometry as a standard method for Hg determination in green coke and oily sludge samples . Atomic adsorption spectrometric analysis (AAS) was used to characterize monometallic oil-soluble Mo or Ni catalyst .

Colorimetric determination of Fe, Ni, and V

Colorimetric analysis carried out using a smartphone camera was reported in the literature . These studies show the possibility of using a high-resolution camera to determine the quantity of phosphorus, chlorine, and methamphetamine. Moonrungsee et al. found that the ambient light intensity seriously affected the color of a picture. The results were more precise in the cabinet using a single LED light. An analysis based on red (R), green (G), blue (B), and intensity values of color showed good correlations with the results obtained by sophisticated techniques. Published articles demonstrated the potential for the development of accurate, rapid, quantitative, and real-time determination methods using the digital camera of smartphone .

It was reported that Matlab software can be used to analyse the R, G, B values for the colorimetric determination of iron content. The results showed greater accuracy compared to UV-visible spectrophotometry .

Anode properties

Two types of anodes (Soderberg and prebaked) are used in the electrolytic cells . Raw material is continuously fed when Soderberg anode is used, and this produces lots of volatile gases containing PAH (polycyclic aromatic hydrocarbons). On the other hand, prebaked anodes need to be replaced at regular time intervals. The advantage of prebaked anodes is that they are compacted and it is easy to maintain their quality (compared to Soderberg anodes). This leads to lower carbon consumption as well as makes it easier to control the fumes produced during the baking of anodes . Due to technical and environmental reasons, prebaked anodes are commonly used in the aluminum reduction process, especially in modern smelters. High density and consistent quality anodes are important in the electrolytic process.

Density

Typical industrial anodes have a green density (GAD) in the range of 1.55-1.65 g/cm3, a baked density (BAD) between 1.50-1.60 g/cm3, and a baking loss or volatile loss of around 4.5-6 % during baking .

Low baked density implies high porosity which leads to low mechanical strength, high elasticity, low thermal conductivity, and high permeability . It is well known that high gas permeability results in high anode consumption. Thus, high porosity increases the air and CO2 reactivities and the electrical resistivity. High baked density reduces air permeability and extends anode life .

However, extremely high density leads to thermal shock problem. The optimum baked density depends on the raw materials, aggregate granulometry, mixing and forming conditions, process parameters, and pitch content. Anode quality improves when the baked anode density stays in the optimal range.

Apparent density of anode samples (cores) are measured using the ASTM D5502-00 standard.

Electrical resistivity

High electrical resistivity results in high energy consumption and reduces efficiency and economy of the electrolytic process. Typical industrial anodes have electrical resistivities of around 50-60 μΩm . The electrical resistivity of baked anodes is much lower compared to that of green anodes. A decrease in electrical resistivity of a baked anode results in an increase in its thermal conductivity. However, too high a thermal conductivity increases the anode surface temperature, causing excess carbon consumption (air-burn, dust formation) . The electrical resistivity is related to both anode density and cracks in the anode. Denser anodes have fewer cracks and thus lower electrical resistivity as dense anodes contain low porosity. The ASTM D6120-97 standard is used to measure the electrical resistivity of anode samples (cores) .

CO2/air reactivity

During the production of aluminium by the electrolytic reduction of alumina, carbon anodes are predominantly consumed according to Equation. A certain quantity of CO is also produced when CO2 further reacts with anode carbon; this increases anode consumption. Also, air diffuses through the alumina layer covering the top of the anode and reacts with the carbon anode; this is another cause of anode over-consumption. Excess carbon consumption occurs due to (a) air burn (air reactivity); (b) carboxy attack (CO2 reactivity); and (c) dusting (selective oxidation). These are also grouped into chemical consumption and physical consumption. In chemical consumption, air and CO2 react with the anode, and carbon is consumed due to the reaction. During physical consumption, a part of the coke or pitch detaches from the anode and falls into the electrolytic cell. The inherent cause of physical consumption can be due to the deterioration of anode structure since air/CO2 gases react with carbonized pitch and coke present in anode to different extents. This reactivity imbalance weakens the structure, and the physical loss of carbonized pitch and coke occurs. This process is called dusting.

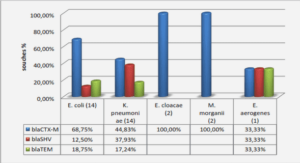

The influence of impurities on CO2 and air reactivities

Carbon anodes contribute significantly to the cost of primary aluminum production. The oxidation of anodes by air and CO2 causes extra carbon consumption. A study described that air and CO2 reactivities have a medium to strong positive correlation with the level of metallic impurities such as nickel, iron, and vanadium .

A number of researchers found that nickel does not have any significant effect on the air and CO2 reactivities.On the other hand, some researchers reported that it can catalyze both CO2 and air reactivities . In spite of the variations in the opinions of various researchers regarding the effect of nickel, they always observed that, an increase in sulfur content can reduce the effect of nickel in the

range of nickel concentrations studied.Casada et al. found that nickel alone does not affect the air/CO2 reactivities of anode, but it can increase CO2 reactivity in the presence of butt particles .

It is difficult to judge the effect of nickel on anode reactivity as the nickel content of coke is highly related to the vanadium content. Recently, Nian-Bing et al. found that the presence of the right amount of Ni (between (210~710 ppm) can inhibit the reactivity and reduce the mass loss rate and dusting of carbon anode by CO2 or air reactivities. It is difficult to study the effect of nickel only due to the presence of other impurities. The conflict of different views on effects of Ni is probably due to the presence of other impurities and their quantities.

Sulfur concentration can influence the effect of nickel. In low-sulphur anodes, it was found that the CO2 reactivity increases with increasing baking temperature . The reason for this increase is that nickel and nitrogen can form nickel nitrides and stay in anodes, and these nitrides decompose at elevated temperatures in carbon dioxide environment. In this process, nickel compounds are reduced and form metallic nickel, which may catalyze the CO2 reactivity.

Artificial network analysis (ANN)

Artificial neural network (ANN) is an important tool in predicting the values of dependent parameters when there is no known relation that exists . Neural networks are inspired by biological nervous systems . They are used to find patterns, to express an output parameter as a function of a number of input parameters, and to predict the value of an output parameter for a set of input parameters. It contains different interconnected layers (input layer, hidden layers and the output layer). Construction of the artificial neural network model, training, validation and prediction of output for a desired set of input parameters are the main steps of an artificial neural network model development.

Artificial neural network models have been used in a diverse range of chemical engineering applications. In one study, it has been used to show the effect of pitch percentage and coke porosity on the CO2 reactivity of anodes . Another research used ANN to reveal that hardness increased with total alloy loading, whilst the corrosion rates did not show any clear relationship with alloy loading. ANN results contributed to an understanding of compositional effects on the corrosion of Mg, and can predict corrosion resistance of Mg alloys .

Although these models were used in different fields as explained above, they were rarely applied to carbon anodes used in aluminum industry . Different ANN models were developed for anodes and cokes within the frame of the UQAC/AAI Chair on carbon.

In the current study, an ANN model is applied in order to predict the effect of metallic impurities on anode reactivity.

|

Table des matières

CHAPTER 1 INTRODUCTION

1.1 Background

1.2 Statement of the problem

1.3 Objectives

1.4 Methodology

1.5 Scope

CHAPTER 2 LITERATURE REVIEW

2.1 The carbon anode

2.2 Anode raw materials

2.2.1 Coke

2.2.2 Butts

2.2.3 Recycled anodes

2.2.4 Pitch

2.3 Impurities in coke and anode

2.4 Different methods to estimate Fe, Ni, and V

2.4.1 Inductively Coupled Plasma Spectrometry

2.4.2 X-ray Fluorescence Spectroscopy (XRF)

2.4.3 Colorimetric determination of Fe, Ni, and V

2.5 Anode properties

2.5.1 Density

2.5.2 Electrical resistivity

2.5.3 CO2/air reactivity

2.6 The influence of impurities on CO2 and air reactivities

2.7 Artificial network analysis (ANN)

CHAPTER 3 EXPERIMENTAL SET-UP AND TEST PROCEDURES

3.1 Materials used

3.2 Colorimetric reactions

3.3 Equipment used

3.3.1 Datacolor Check II

3.3.2 Custom set-up using a webcam

3.3.3 Electrophoresis set-up

3.3.4 Thermogravimetric analyzer for reactivity measurements

3.4 Development of calorimetric methods

3.4.1 Development of colorimetric methods for the estimation of Fe, Ni, and V in anode samples

3.4.2 Study of the effect of impurities on the reactivities of anodes

3.4.3 Artificial Neural Network modelling

CHAPTER 4 RESULTS AND DISCUSSIONS

4.1 Development of colorimetric methods for the estimation of Fe, Ni, and V in anode samples

4.1.1 Identification of conditions for the reaction between the impurity and the reagent using Datacolor

4.1.2 Measurement of change in color components using the custom-made set-up with the webcam

4.2 Study of the effect of impurity content on anode reactivities

4.2.1 Characterization of the green anodes

4.2.2 Characterization of cylindrical anode samples used for reactivity studies

4.2.3 Reactivities of different anode samples

4.2.4 Effect of different impurities on anode reactivities

4.3 Results of ANN

4.3.1 The effect of iron (Fe) concentration on air and CO2 reactivities (V, Ni, and S maintained at their typical levels)

4.3.2 The effect of vanadium (V) concentration on air and CO2 reactivities (Fe, Ni, and S were maintained at their typical levels)

4.3.3 The effect of nickel (Ni) concentration on air and CO2 reactivities (Fe, V, and S were maintained at their typical levels)

4.3.4 The effect of sulfur (S) concentration on air and CO2 reactivities (Fe, V, and Ni were maintained at their typical levels)

4.3.5 Remarks

CHAPTER 5 CONCLUSIONS AND RECOMMENDATIONS

5.1 Conclusions

5.2 Recommendations

![]() Télécharger le rapport complet

Télécharger le rapport complet